BPA & phthalates (and other plasticizers) migrate, leach, and flake from plastics

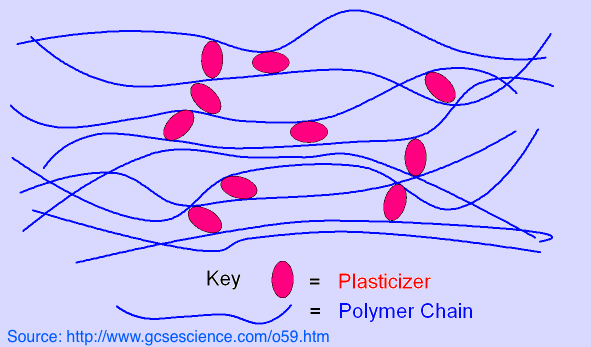

BPA & phthalates migrate, leach and flake off of plastics primarily because they are not chemically bound to the plastic.

This ad-free article is made possible by the financial support of the

Center for Research on Environmental Chemicals in Humans: a 501(c)(3) non-profit.

Please consider making a tax-deductible donation for continued biomedical research.

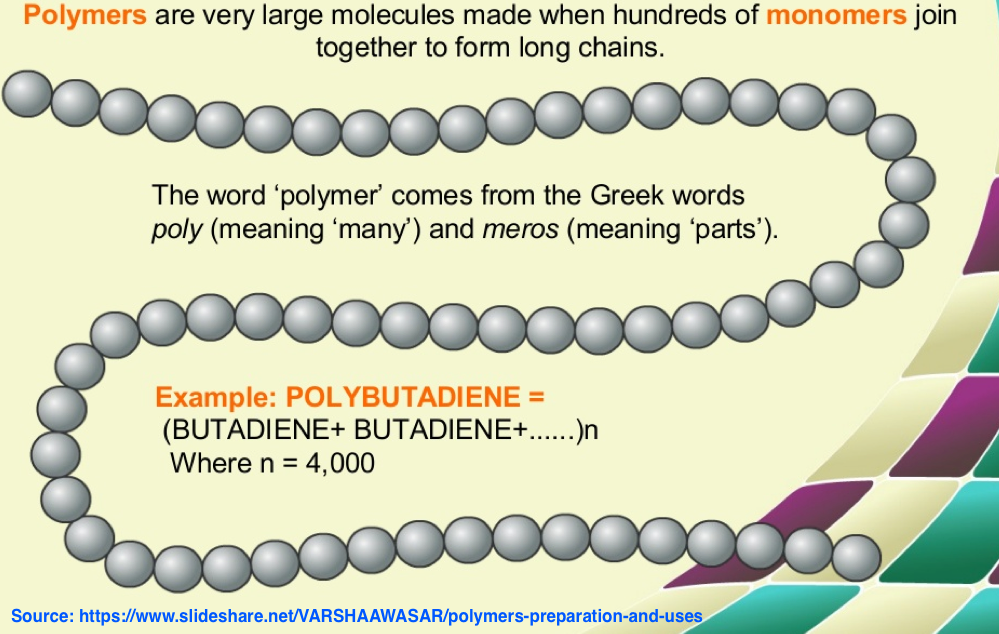

It’s important to understand that any specific plastic is a mixture of one or more polymers along with a variety of additives like BPA and phthalates that are added to provide desired characteristics such as color, strength, rigidity (or flexibility), and other qualities of the finished plastic.

This ad-free article is made possible by the financial support of the

Center for Research on Environmental Chemicals in Humans: a 501(c)(3) non-profit.

Please consider making a tax-deductible donation for continued biomedical research.

In some ways, polymers are like dry cement. Water can be added, and a hard substance results when it cures. Aggregates like sand and stone are mixed in to provide strength. Steel rebar is added for flexibility and tensile strength. Polymer fibers offer flexibility. Dyes are added for color.

An exothermic chemical reaction takes place when water is added to cement. But the sand, stones and re-bar are not part of the chemical reaction.

Just like plasticizers added to plastics, the additives to cement are not covalently bound to the concrete. Instead, those additives — whether to concrete or a plastic — are physically confined when the mixture cures, but can separate under many circumstances.

Rebar, stones, and even sand are massive compared with the tiny sizes of the plasticizer and additive molecules that give polymer chains the desired characteristics. Because of this, additives can migrate among the polymer chains and — when they reach the surface of the plastic — can easily leach or simply fall out of the plastic-like pebbles from old concrete.

What helps additives escape from the plastic?

Additives escape from plastic and enter the food chain or directly into people’s bodies through a combination of actions that include:

Mechanical- Scraping, friction, bending, stretching, twisting, or compressing plastic promotes microfractures that speed additive particles toward a surface. Friction between plastics or other components can create fine dust particles that accelerate the release of additives.

Mechanical stressors are particularly applicable to conveyor belts, squeezable condiment containers, plastic utensils in contact with plastic bowls or paper plates (most of which have a plastic coating), plastic gloves, and plastic beverage containers.

Children frequently treat their plastic toys and other objects with less than tender loving care.

Light – Degrades plastic and accelerates the release of plastic additives.

Chemical action – Acidic foods and beverages can react with a variety of additives because those are not chemically bound (covalently) to the polymers. Some polymers may also be subject to reacting with acids or other food and beverage compounds.

Lipophilia – Promotes absorption of chemicals in oil-based foods. Studies show that people can absorb BPA from touching thermal paper cash receipts. What’s more, those who use hand moisturizers absorb far more BPA because of the increased lipids from the hand cream.

Heat – Adds energy to the migration process, speeds up chemical reactions that can loosen bonds.

Processing

Why food processing adds contamination

Contamination of basic foods — even those that do not undergo extensive processing — comes from:

- Contact with contaminated soil and water during planting, irrigation, and growth.

- Exposure to plastics during harvest from conveyor belts, chutes, pipes, baffles, and other equipment.

- Exposure to plastic in the washing process through the use of bins, tanks, implements, and pipes.

- Exposure to plastics during the drying and packing stages including the use of recycled or coated cardboard.

Contamination through processing

This article from the British Medical Journal offers a look at many of the substances added to highly processed foods: Consumption of ultra-processed foods and cancer risk: results from NutriNet-Santé prospective cohort

While the BMJ article focused on the nutritional downsides to processing, it’s vital to recognize that each processing operation and additive — regardless of nutritional value — brings with it its own unique contamination trail and chemical burdens that are incorporated into a highly processed food product for sale.

Specific contamination routes found in individual food groups are discussed elsewhere in this document.

Degree of food processing

We categorized all food and drink items of the NutriNet-Santé composition table into one of the four food groups in NOVA, a food classification system based on the extent and purpose of industrial food processing.

This study primarily focused on the “ultra-processed foods” NOVA group.

This group includes mass-produced packaged breads and buns; sweet or savoury packaged snacks; industrialized confectionery and desserts; sodas and sweetened drinks; meatballs, poultry and fish nuggets, and other reconstituted meat products transformed with the addition of preservatives other than salt (for example, nitrites); instant noodles and soups; frozen or shelf-stable ready meals; and other food products made mostly or entirely from sugar, oils and fats, and other substances not commonly used in culinary preparations such as hydrogenated oils, modified starches, and protein isolates.

Industrial processes notably include hydrogenation, hydrolysis, extruding, molding, reshaping, and pre-processing by frying. Flavoring agents, colors, emulsifiers, humectants, non-sugar sweeteners, and other cosmetic additives are often added to these products to imitate the sensorial properties of unprocessed or minimally processed foods and their culinary preparations or to disguise undesirable qualities of the final product.

The ultra-processed food group is defined by opposition to the other NOVA groups: “unprocessed or minimally processed foods” (fresh, dried, ground, chilled, frozen, pasteurized, or fermented staple foods such as fruits, vegetables, pulses, rice, pasta, eggs, meat, fish, or milk), “processed culinary ingredients” (salt, vegetable oils, butter, sugar, and other substances extracted from foods and used in kitchens to transform unprocessed or minimally processed foods into culinary preparations), and “processed foods” (canned vegetables with added salt, sugar-coated dried fruits, meat products preserved only by salting, cheeses, freshly made unpackaged breads, and other products manufactured with the addition of salt, sugar, or other substances of the “processed culinary ingredients” group).

Lipophilia: for the love of fat

In scientific terms, fats and oils are known as lipids. Lipophilia means a “love of lipids.” Fats tend to be solid (or relatively so) at room temperature and oils, liquid.

Significantly, BPA, phthalates, and many other harmful environmental chemicals are “lipophilic” — they are easily dissolved in fats and oils.

This should not be surprising because most environmental chemicals — including endocrine disruptors and pesticides — are derived from petroleum. The same goes for artificial fragrances, flavor enhancers and food coloring as well as plastics in general, and the printing inks used on them.

What this means is that contact between plastic and any form of food-based oil or fat results in increased migration of BPA, phthalates, and other chemicals from the plastic and into the edible portions of the food.

While there is no valid science yet, there is a logical possibility that the health stigma of fat in the diet and its role in obesity may be due more to the presence of harmful environmental chemicals in the fat, rather than its metabolism and actual calorie count.

Scores of well-designed, peer-reviewed, published studies have shown that BPA and phthalates act as “obesogens” — substances that disrupt the metabolic process and result in the preferential storage of fat rather than its use as energy.

Why does lipophilia matter?

The opposite of lipophilic is hydrophobic — the fear of water. This means that harmful environmental chemicals are somewhat less likely to leach into foods and beverages that are water-based.

Despite that, BPA (hydrophobic) still leaches into the water of plastic bottles.

The migration of BPA, phthalates, and other lipophilic chemicals is preferentially accelerated when placed in contact with lipids — fats and oils — whether from foods like bacon or cooking oils.

This means that even very heart-healthy foods like olive oil packed in plastic bottles could contain higher concentrations of BPA and phthalates than those in glass bottles.

Impacts cooking and processing

Lipophilia impacts both cooking and processing.

In cooking, the BPA and phthalates in plastic mixing bowls, utensils, and other items can migrate into the foods themselves.

Heat will further encourage migration of chemicals from plastics. This includes microwaving food in plastic, allowing warm or hot foods to come into contact with plastic bowls, dishes, or cooking with plastic utensils.

The spice lipo-paradox

Spices have evolved over the centuries as effective ways to preserve foods from spoiling and to disguise the taste of items that have started to decompose.

By themselves, many spices also have beneficial health properties, as evidenced most recently by studies showing turmeric’s potential cancer-fighting properties. (Spices for Prevention and Treatment of Cancers).

On the other hand, a number of studies have found that spices often have very high and variable concentrations of phthalates. Those studies have posited that the contamination comes from extensive handling and processing.

While the flavor ingredients in spices are sometimes water-soluble, most spice flavors come from lipid-soluble compounds. This is why cooks will often saute spices in oil before adding aqueous ingredients. This process, known as “blooming,” intensifies the flavor because the oil extracts the lipid components at a temperature hotter than that of the boiling point of water.

Blooming is useful when cooking at high altitudes where the boiling point of water is lower than at sea level. This means the extraction of spice flavors drops, resulting in blander foods. At Lake Tahoe, for example, water boils at 94°C, something that prevents full flavor extraction, even with longer cook times.

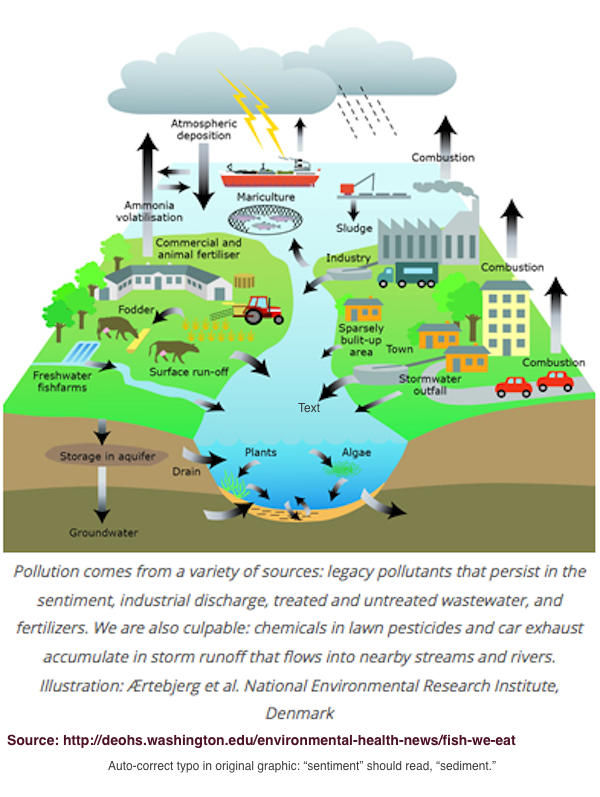

Water & fertilizers: Ubiquitous contamination sources

Irrigation water – farm ponds, biosolids, and recycled municipal wastewater

With rare exceptions, irrigation involves plastic pipes, tanks, tubing, drip devices, and valves which leach varying amounts of plastic chemical contaminants.

Well water may be the purest source, but is less available as water tables drop from drought and over-pumping. The distribution lines of a well are usually plastic.

Municipal water may be the second-best source depending upon the treatment methods, filtering, and added chemicals. However, municipal water distribution is increasingly using plastic pipes for mains and secondary distribution lines.

Farm ponds are questionable for direct use because of wildlife, livestock, and other uses in the upstream drainage area.

In addition to BPA and phthalates, recycled municipal wastewater contains scores of harmful chemicals including pharmaceuticals, illegal narcotics, and other undesirable compounds that can find their way into animal flesh and meat.

- Contaminants of Emerging Concern in the Environment

- Nationwide reconnaissance of contaminants of emerging concern in source and treated drinking waters of the United States

- Simultaneous determination of 148 pharmaceuticals and illicit drugs in sewage sludge

- Wastewater Treatment Plants as Chemical Observatories to Forecast Ecological and Human Health Risks of Manmade Chemicals

- Risks associated with the environmental release of pharmaceuticals on the U.S. Food and Drug Administration “flush list

- Pharmaceuticals occurrence in a WWTP with significant industrial contribution and its input into the river system

- A review on emerging contaminants in wastewaters and the environment: Current knowledge, understudied areas and recommendations for future monitoring

- Risks and Benefits of Tertiary Sewage Effluent as Drinking Water

- Prioritization of Contaminants of Emerging Concern in Wastewater Treatment Plant Discharges Using Chemical:Gene Interactions in Caged Fish

- Drug residues in urban water: A database for ecotoxicological risk management

- Veterinary pharmaceutical contamination in mixed land use watersheds: from agricultural headwater to water monitoring watershed

Reviews of the use of recycled municipal wastewater indicate that contaminates remain in the water and can be absorbed the tissues of growing plants.

- Major Study Indicts Chemicals Found in Recycled Wastewater Used For Vineyards And Other Crops

- Recycled Wastewater In The Wine Vineyard: Unknowns, Health Hazards, Brand Issues

- Wastewater Recycling Controversy

Significantly, commercial hay fields are frequently fertilized to increase production. That fertilizer may be a commercial product, or biosolids — sludge from sewage treatment plants which frequently contain heavy metals.

Highlights

•Relative potency determined for six individual contaminants in a suite of bioassays

•Multiple-modes of action of individual contaminants demonstrated in different in vitro assays

•Comprehensive assessment of potential in vitro effects associated with carbamazepine

Abstract

The use of biosolids as a soil conditioner and fertiliser is hindered by the limited knowledge on the risks of micro-contaminants they contain. This study investigated the binding of six organic contaminants commonly found in biosolids, to the estrogen (ER), androgen (AR), aryl hydrocarbon (AhR), and transthyretin (TTR) receptors and their redox activity. Triclosan (TCS), bisphenol-A (BPA), and technical nonylphenol (TNP) had affinity for the TTR with relative potencies of 0.3, 0.03, and 0.076 respectively. Further, binding to TTR was the only toxicological response observed for carbamazepine, which induced sub-maximal response and relative potency of 0.0017. Estrogenic activity was induced by BPA, galaxolide (HHCB), diethylhexyl phthalate (DEHP) and TNP with BPA having the strongest potency of 5.1 × 10−6 relative to estradiol. Only BPA showed androgenic activity but it was not quantifiable. BPA also showed anti-androgenic activity along with TCS, HHCB, and TNP in the order of TNP > HHCB > TCS ~ BPA (relative potencies 0.126, 0.042, 0.032, 0.03). No compounds exhibited anti-estrogenic or AhR activity, or were redox-active in the dithiothreitol assay. The results highlight the multiple modes of action through which these compounds may impact exposed organisms, and the concentrations at which effects may occur. This allows assessment of the likelihood of effects being observed at environmental concentrations, and the potential contribution of these compounds.

Biosolid Risks

Unfortunately, papers in the last couple of years are pointing toward biosolids as a source of microplastics, drug-resistant bacteria, and genes, as well as artificial estrogens and other endocrine disuptors.

The safe and environmentally responsible use of biosolids is a goal worth striving for. However, biosolids are not — yet — ready for prime time. Below is a small sample of recent published studies that point to the need for more caution and the need for further research to protect public health.

Contamination by E. Coli and other pathogens

Highlights

•Biosolids-derived emerging contaminants found in simulated rainfall runoff

•Biosolids are a potential source of anthropogenic contaminants to surface waters

•Runoff contaminant concentrations relatively constant across multiple rain events

•Intense and frequent precipitation dramatically increases contaminant load

•Some contaminants undergo in situ attenuation unrelated to precipitation events

Abstract

The presence of anthropogenic contaminants such as antimicrobials, flame-retardants, and plasticizers in runoff from agricultural fields applied with municipal biosolids may pose a potential threat to the environment. This study assesses the potential for rainfall-induced runoff of 69 anthropogenic waste indicators (AWIs), widely found in household and industrial products, from biosolids amended field plots. The agricultural field containing the test plots was treated with biosolids for the first time immediately prior to this study. AWIs present in soil and biosolids were isolated by continuous liquid-liquid extraction and analyzed by full-scan gas chromatography/mass spectrometry. Results for 18 AWIs were not evaluated due to their presence in field blank QC samples, and another 34 did not have sufficient detection frequency in samples to analyze trends in data. A total of 17 AWIs, including 4-nonylphenol, triclosan, and tris(2-butoxyethyl)phosphate, were present in runoff with acceptable data quality and frequency for subsequent interpretation. Runoff samples were collected 5 days prior to and 1, 9, and 35 days after biosolids application. Of the 17 AWIs considered, 14 were not detected in pre-application samples, or their concentrations were much smaller than in the sample collected one day after application. A range of trends was observed for individual AWI concentrations (typically from 0.1 to 10 μg/L) over the course of the study, depending on the combination of partitioning and degradation mechanisms affecting each compound most strongly. Overall, these results indicate that rainfall can mobilize anthropogenic contaminants from biosolids-amended agricultural fields, directly to surface waters and redistribute them to terrestrial sites away from the point of application via runoff. For 14 of 17 compounds examined, the potential for runoff remobilization during rainstorms persists even after three 100-year rainstorm-equivalent simulations and the passage of a month.

Antibiotic Resistance

ABSTRACT

Antibiotic resistance has emerged globally as one of the biggest threats to human and animal health. Although the excessive use of antibiotics is recognized for accelerating the selection for resistance, there is a growing body of evidence suggesting that natural environments are “hotspots” for the development of both ancient and contemporary resistance mechanisms. Given that pharmaceuticals can be entrained onto agricultural land through anthropogenic activities, this could be a potential driver for the emergence and dissemination of resistance in soil bacteria. Using functional metagenomics, we interrogated the “resistome” of bacterial communities found in a collection of Canadian agricultural soil, some of which had been receiving antibiotics widely used in human medicine (macrolides) or food animal production (sulfamethazine, chlortetracycline and tylosin) for up to 16 years. Of the 34 new antibiotic resistance genes (ARGs) recovered, the majority were predicted to encode for (multi)drug efflux systems, while a few share little to no homology with established resistance determinants. We characterized several novel gene products, including putative enzymes that can confer high-level resistance against aminoglycosides, sulfonamides, and broad range of beta-lactams, with respect to their resistance mechanisms and clinical significance. By coupling high-resolution proteomics analysis with functional metagenomics, we discovered an unusual peptide, PPPAZI 4, encoded within an alternative open-reading frame not predicted by bioinformatics tools. Expression of the proline-rich PPPAZI 4 can promote resistance against different macrolides but not other ribosomal-targeting antibiotics, implicating a new macrolide-specific resistance mechanism that could be fundamentally linked to the evolutionary design of this peptide.

IMPORTANCE

Antibiotic resistance is a clinical phenomenon with an evolutionary link to the microbial pangenome. Genes and protogenes encoding for specialized and potential resistance mechanisms are abundant in natural environments, but understanding of their identity and genomic context remain limited. Our discovery of several previously-unknown antibiotic resistance genes from uncultured soil microorganisms indicates that soil is a significant reservoir of resistance determinants, which, once acquired and “re-purposed” by pathogenic bacteria, can have serious impacts on therapeutic outcomes. This study provides valuable insights into the diversity and identity of resistance within the soil microbiome. The finding of a novel peptide-mediated resistance mechanism involving an unpredicted gene product also highlights the usefulness of integrating proteomics analysis into metagenomics-driven gene discovery.

Plastic Pollution

The growing evidence of an environmental crisis caused by plastics in both fresh and seawater offers further reasons for concern.

While vast floating islands of plastic afflict parts of the oceans, the larger danger to humans may be due to the vast qualities of wastewater entering rivers, streams, and estuaries.

That wastewater carries significant concentrations of hundreds of dangerous chemicals, pharmaceuticals, illegal drugs, BPA, phthalates, pesticides, household chemicals, and more.

These are in addition to microfibers which are already building up on land irrigated with recycled wastewater.

Organic fertilizer as a vehicle for the entry of microplastic into the environment

Abstract

The contamination of the environment with microplastic, defined as particles smaller than 5 mm, has emerged as a global challenge because it may pose risks to biota and public health. Current research focuses predominantly on aquatic systems, whereas comparatively little is known regarding the sources, pathways, and possible accumulation of plastic particles in terrestrial ecosystems. We investigated the potential of organic fertilizers from biowaste fermentation and composting as an entry path for microplastic particles into the environment. Particles were classified by size and identified by attenuated total reflection-Fourier transform infrared spectroscopy. All fertilizer samples from plants converting biowaste contained plastic particles, but amounts differed significantly with substrate pretreatment, plant, and waste (for example, household versus commerce) type. In contrast, digestates from agricultural energy crop digesters tested for comparison contained only isolated particles, if any. Among the most abundant synthetic polymers observed were those used for common consumer products. Our results indicate that depending on pretreatment, organic fertilizers from biowaste fermentation and composting, as applied in agriculture and gardening worldwide, are a neglected source of microplastic in the environment.

Nano-Contamination

The increased use of nanoparticles in clothing, toothpaste, personal care products and other items are finding their way into the municipal wastewater stream. In addition to chemical leaching, some nanoparticles may be small enough to be absorbed directly into the blood streams of fish and other animals.

- Soil microbial community responses to contamination with silver, aluminium oxide and silicon dioxide nanoparticles

- TiO2 nanoparticles and sludge from wastewater treatment plants: a new concern for crops?

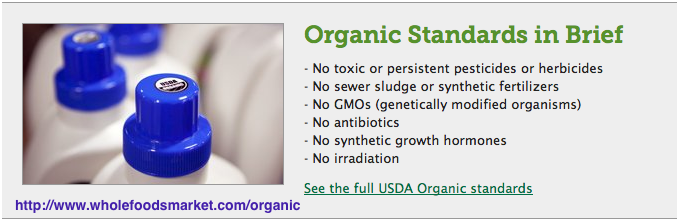

Whole Foods, in 2014, banned vegetables fertilized with biosolids, but the practice remains controversial:

- Whole Foods Bans Sludge Fertilizer

- Whole Foods Bans Produce Grown With Sludge. But Who Wins?

- Health risks associated with wastewater use

- Wastewater Reuse in Agriculture and Potential Risks to Human Health

- Standards for Irrigation and Foliar Contact Water – The Pew Charitable …

- High levels of microbial contamination of vegetables irrigated with wastewater by the drip method.

- Effect of biofilm in irrigation pipes on microbial quality of irrigation water.

- Microbial contamination of vegetable crop and soil profile in arid regions under controlled application of domestic wastewater.

- Escherichia coli contamination and health aspects of soil and tomatoes (Solanum lycopersicum L.) subsurface drip irrigated with on-site treated domestic wastewater.

- Monitoring the occurrence of pharmaceuticals in soils irrigated with reclaimed wastewater

SECTION II

Sourcing the Menu: Standards and Choice Limitations

Meat the enemy

Animal flesh presents an especially tough issue when it comes to systematic contamination by endocrine disruptors and other harmful environmental chemicals. Dairy (to be dealt with in the next section) presents even more opportunities for contamination.

While plastic food contact materials present one of the most visible contamination sources, human contamination from consuming meat begins with animals consuming contaminated food and water.

The following emphasizes cattle, but the contamination sources are mostly analogous for sheep, poultry, and pigs. Variations among species will be noted after common contamination pathways are described.

Commercial cattle and other farm animal feed suffers from the same plastic contamination as other highly processed products involving conveyor belts, plastic pipes, tubing, and contact with other polymer-based machinery.

In addition, the “finishing” process by which cattle and livestock are fattened before slaughter involves numerous undesirable chemicals, but also involves grain which is another category of food with contamination problems from farm to table.

Cattle and livestock that forage in pastures or which are fed hay might seem to offer a lower burden of environmental chemicals. This would be the case if the fields from which the hay is harvested has not been irrigated.

Because of the expense of installing permanent irrigation sprinklers, pasture irrigation is often accomplished through the use of mobile sprinkler heads connected to a water source by means of plastic hoses that are frequently 100 yards long or greater.

(Example: K-Line irrigation)

Contaminates leaching from the long irrigation hoses are compounded if the water source is highly treated recycled municipal wastewater.

Cattle grazing on wastewater-irrigated fields contaminate themselves by eating moist, recently irrigated grass, or grass that is dry but which is coated with wastewater chemical residues.

Searches for studies on concentrations of chemicals of concern in livestock and their flesh could find little other than one which showed severe health effects in sheep that grazed on pasture fertilized with biosolids.

Grass-fed healthy alternative, but often abused

Grass-fed beef and other livestock offer relief from the excessive chemical, pharmaceutical, and dietary practices used by industrial producers to produce maximum meat in minimum time and less money. Such factory farming has seen many health abuses in both the livestock and meat consumers.

However, even the grass-fed process has been abused (Grass-Fed Beef Loses Its Luster) by operators who employ factory-style, crowded feedlot practices.

An entire industry has developed where hay or other grass products are formed into feed pellets along with growth enhancers which are fed to cattle subsequently marketed as “grass-fed.”

From: Grass-Fed Beef Loses Its Luster

“A growing number of consumers began turning to grass-fed beef in order to avoid buying meat from feedlot cattle and factory farms. “But as grass-fed beef skyrocketed in popularity,” Lowry points out, “these same large producers have jumped on the bandwagon to offer a product that meets the letter of the law without a lot of respect for the spirit.”

Lowry explains that beef– technically grass-fed and grass-finished–is in fact coming from concentrated feedlots where the cattle are fed from troughs of manufactured grass pellets. “Large scale farms are talking about how to dope their grass with nitrogen,” Lowry says, and undernourished cattle are getting sold to the consumer at a premium because they have the “grass-fed” label.

The American Grassfed Association has issued a set of guidelines outlawing the pellets, crowded conditions, and other animal welfare abuses.

While true grass-fed beef offers a healthier alternative when done to standards, (Membership and Certification Submission Checklist), even those operations need to be certain that pastures and any supplemental hay and feedings done when pasturing is impossible, are free of irrigation and other harmful environmental chemical contamination.

This probably isn’t what most people think they’re signing up for. But if you’re buying “grass-fed” beef and you can’t name the farmer or locate the farm on a map, it’s a good bet you’re getting pellets, not pasture.”

Chicken & pork

Factory farming for chicken and pork has paralleled beef in intensity and opportunities for contamination in animal concentration, feeding for swift, maximum growth, and processing after slaughter.

Organic regulations requiring space for animal welfare and feed ameliorate some of the contamination issues of mainstream husbandry. Potential issues remain with water sourcing as well as irrigation and growing conditions for feed which is seasonally required even for free-range animals.

The EU found environmental chemicals in feed and chicken coop construction materials in flesh and eggs. This was confirmed by a Belgian study and others.

Sausage: the original processed food (Now in plastic casings!)

Sausage of various sorts has been used for centuries to stuff animal intestines with various bits and pieces of meat, organs, and offal that are unsuitable, unpalatable, or impractical to serve in their natural state.

Over the centuries, various fillers, spices, preservatives, emulsifiers, and other substances have been added to the meat bits. Modern sausage — especially the ubiquitous hot dog — is more often than not in a manufactured synthetic casing usually made of polymers and packed with meat of various origins ground into a paste with fillers and binders.

Spices, which have a lipophilic effect in attracting BPA and phthalates, are often used to cover up the off-tastes in sausages and other manufactured foods.

Replicant meat

Frozen and pre-prepared meals, as well as sliced cold-cuts, are usually replicant meat — created from manufacturing processes designed to be made mostly of meat, binders, and other substances which are then molded to look resemble the real thing.

The associated use of “mechanical fingers” and chemical solutions designed to strip every last shred of meat from bones have introduced a new category of semi-fake meat that is artificially formed from meat fragments, glued together with a host of mostly undisclosed substances, and re-formed either into “nuggets” or shaped to look like a whole, natural piece of meat — sometimes with fake painted/printed-on “grill” marks made of yet another chemical composition.

Many of the ingredients in these are not publicly available because the companies have classified them as trade secrets, something allowed by regulators.

Burgers

In their own way, burgers resemble sausage without a casing. And, like sausage, burgers — whether beef, chicken, fish, or veggie are fertile ground for undisclosed additives. One of the most notorious of the additives in hamburgers, as well as chicken nuggets, and manufactured meat designed to look like the real thing is the notorious “Pink Slime.”

The chicken AND the egg? A fowl situation

Both the flesh and the eggs of chickens and other edible fowl have the same issues with opportunities for contamination from feed and water as other farm animals.

Fishy business

Fish contamination occurs in growth, harvest, processing, and sales. But because edible fish grow in polluted oceans and freshwater lakes, rivers, and streams, they can accumulate contaminates from many sources in their natural environment.

- U.S. Agency Study Finds Toxic Chemicals in Fish is Widespread

- Chemicals in Fish

- Bioaccumulation of super‐lipophilic chemicals in fish

Because chemical contamination grows with time, this set of recommendations from the state of Washington recommends eating smaller, younger fish. It also recommends cutting away the fatty portions of fish such as salmon because some chemicals are lipophilic. Other contaminants such as methyl mercury, are water-soluble.

Beware of farmed fish

Studies have determined that farmed fish are subject to contamination by multiple chemicals (Friends Don’t Let Friends Eat Farmed Salmon). The feed is one suspect as are chemicals and pharmaceuticals added to keep fish as healthy as possible in crowded pens.

Plastic Pollution

The growing evidence of an environmental crisis caused by plastics in both fresh and seawater offers further reasons for concern.

While vast floating islands of plastic afflict parts of the oceans, the larger danger to humans may be due to vast qualities of wastewater entering rivers, streams, and estuaries which are used for irrigation and other agricultural uses.

Dairy: Milk & Cheese

The contamination of the dairy chain starts with what the female mammal — aka “cow” — consumes. This is most often a bovine cow in America, but globally includes goats, sheep, and other mammals. (see “Meat the enemy”)

The milk from cows — like its flesh and that of its male counterparts — can be contaminated with environmental chemicals from its food and water.

But the milk produced will be further contaminated by many additional processes before milk, cheese, yogurt, and the whey for dietary supplements reaches a human consumer.

The introduction of plastic chemicals into the dairy food chain begins with the milking process and continues to increase at each step before reaching the consumer.

Milking machines

Other than the rare artisan-produced cheese, the hand-milking of cows, goats, and other livestock has mostly vanished. Milking machines make the first step of production more cost-effective, time-efficient, and sanitary — all benefits to the consumer.

Before milking begins, the udder and teats undergo a number of hygiene steps that include cleaning with anti-bacterial solutions (Hygiene in milk production).

This helps ensure the cleanliness of the milk and starts a process to extend the length of time before milk can sour. This also helps prevent injuries to the cow, including mastitis, a serious inflammation of the udder and mammary gland.

- Mastitis is most often transmitted by contact with the milking machine, and through contaminated hands or other materials.

- The Milking Machine and Mastitis

Another anti-bacterial cleaning occurs after milking. All of the cleaning and irritation from the milking machine results in the application of salves.

No research can be found so far on whether antibiotics, salves, and cleaning agents may contaminate the collected milk.

It’s also notable that plastic gloves worn by handlers through the milking process can result in phthalate transfer to the teat. This extent of this transfer is unknown.

In addition, the phthalates and other EDCs in the gloves can leach out and be absorbed through the skin of the wearer. The leaching and transfer is increased by people who use hand creams.

Plastic contamination and the milking machine

Milking machines use a pulsating vacuum to draw raw milk from the udder.

https://hoards.com/images/udder.111.widea.0.gif

The teatcup that attaches to each teat is lined with a flexible plastic (phthalate soft) that alternately compresses and relaxes as the vacuum pump operates.

The milk is drawn into a one-way plastic chamber (known as “the claw”) which allows the milk to be drawn off and transferred into a collection tank that is sometimes plastic, sometimes stainless steel. From the collection tank, milk flows to a bulk tank, frequently via plastic piping or tubing. (How the milking system works)

From the bulk tank at the dairy, milk is transferred via plastic hoses to a tanker truck which reverses the process through plastic hoses to larger tanks at the creamery. All of the processing involves plastic hoses, pipes, fixtures, pumps, valves, vats, vessels, and other equipment that often contain or are made of plastic.

At the creamery, plastic hoses dominate the processes of separating cream from the whole milk. The skimmed milk and cream are usually pasteurized separately.

Some cream is returned to the skimmed milk to create a range of butterfat levels, and some is made into butter. Cheese can be made from milk at a variety of stages in this process.

Lipophilia

Significantly, BPA, phthalates, and many other harmful environmental chemicals are “lipophilic” — they are easily dissolved in fats.

This means that the cream separation process creates a high-fat environment that encourages the leaching of these environmental chemicals into dairy products.

Cheese & Whey

Cheese made from whole milk contains more fat. More fat offers contamination opportunities for lipophilic chemicals like BPA and phthalates.

The cheesemaking process can use plastics at various points, but most likely as utensils, filtering materials, molds for curds, and the process for draining off whey. Further contamination can occur in the processing that cuts large blocks then wraps individual blocks, wheels, and other large shapes. Sliced and grated cheeses expose cheese to contamination as well as the plastic pouches and bags they are packed in.

Most organic cheeses use plastic in their final packaging. The most highly contaminated will be blocks that have been shrink-wrapped. This is because the film is warm/hot when it comes into contact with the cheese. The heat encourages the migration of contamination from the plastic into the cheese.

Whey is a mostly water-loving substance left over from the cheesemaking process. However, studies have shown that many organic contaminants can be bound to the milk proteins.

Fruit & veggies

Vegetables in both the exposure and decontamination phases will be coordinated to accommodate seasonally available local products obtained from USDA-certified organic farms that do not use recycled wastewater for irrigation.

Most fruits and vegetables receive substantial exposure to plastics before they reach the supermarket. This contamination — which also applies to grains for bread, cereal, and pasta — results from the use of plastics during harvest, processing, and packaging for sale.

Most supermarket fruits and vegetables are grown with commercial fertilizers and an increasing percentage are fertilized with biosolids — a euphemism for the sludge from municipal sewage treatment plants.

Due to loosening standards and a lengthening list of “exceptions” to the USDA rules, even certified organic fruits and vegetables can be fertilized and treated with a growing number of commercial chemicals.

Exceptions to the regulations have been made by the USDA without extensive study of the substances involved. Also overlooked are additives, surfactants, and other auxiliary chemicals added to enhance the active ingredients. Those added substances often have endocrine-disrupting or other harmful effects.

From sewer to table

Most American supermarket produce aisles will feature fruits and vegetables irrigated with recycled municipal sewer and wastewater and fertilized with biosolids – sewage sludge.

Published scientific studies have demonstrated that chemicals in recycled wastewater can be absorbed by the edible portions of some fruits & vegetables or remain on the surface after water contact.

Tree-born fruit may have contact contamination, but the distance from the ground to the fruit makes it less likely that contamination will reach edible interior parts.

See: Recycled Wastewater In The Wine Vineyard for more.

Supermarkets okay with sewer-to-store veggies (all but one)

As far as can be determined, Whole Foods is the only grocery chain to ban fruits and vegetables fertilized with sewer sludge: Whole Foods Bans Sludge Fertilizer.

Recycled municipal wastewater (increasingly used for food crops) is currently not prohibited by USDA Organic Standards and is not addressed even by Whole Foods.

Harvesting and processing involve extensive contact with conveyor belts containing phthalates for flexibility and hard plastic rollers whose durability usually results from BPA-containing polycarbonates.

Food contact materials also contribute to contamination since many whole fresh vegetables are wrapped in plastic for sale.

Frozen vegetables

Frozen vegetables receive additional plastic contact in processing, and are packaged in plastic. Some are packaged with directions for the contents to be heated or microwaved while in the plastic bags and containers. Heating in the bag increases the release of environmental chemicals into the food.

Fruit and vegetable juice

The commercial processing of fruit and vegetable juice offers numerous exposure opportunities for contamination. Plastics are extensively present in peeling, crushing, filtering, transport, and in the plastic bottles, pouches, and epoxy can linings.

Going against the grain: Bread and cereal killers

The domestication of grains nearly 11,000 years ago accelerated civilization from hunter-gatherer to the agriculturally based world of today (Ancient Waves of (Wild) Grain).

While bread and cereal products are among the most basic and valuable foodstuffs modern commercial grains are subject to the same the irrigation and fertilization problems associated with fruits and vegetables.

This includes harvest and processing contamination occurrences including the use of questionable irrigation water, commercial fertilizer, and the use of recycled municipal wastewater and sewage sludge biosolids. In addition, wheat is extensively applied with glyphosate and other pesticides.

The issue of irrigation is not as critical because a substantial portion of wheat matures during the winter when rains are more prevalent. A warming climate is expected to affect this.

In addition, the transportation of wheat is a massive bulk operation using barges, ships, and railroad bulk carriers all of which offer ample opportunities for plastic contact with conveyor belts, augers, and other plastic apparatus, and storage. Because of the size of the operation, there is little oversight of transportation.

Flour production involves extensive contact with plastic-based apparatus, conveyor belts, and transport.

Commercial baking: a wonder of automation and processing contamination

The actual making and baking of commercially produced bread, again, involves conveyor belts but also plastic bins used for ingredients, mixing, and preparation for dough. Plastic loaf pans are used for dough in the rising stages.

The baking process usually employs metal conveyor surfaces with the warm loaves going into plastic bags when still warm.

This paper from the British Medical Journal defines commercial bread as a highly processed food: Consumption of ultra-processed foods and cancer risk: results from NutriNet-Santé prospective cohort

Small batch regional bakeries

Most small-batch regional bread bakeries still use commercially available flour with its inherent contamination opportunities.

However, some very small artisan operations — such as those associated with the California Grain Campaign — have reduced their dependence on plastics and pack their product in brown paper bags.

It’s important to recognize that recycled paper carries high concentrations of phthlates because a high percentage of ink used in packaging gets recycled along with the paper.

Corn-based breads and cooking ingredients

Corn is a basic ingredient in many favorite American ethnic foods such as tacos, enchiladas, tamales, and more.

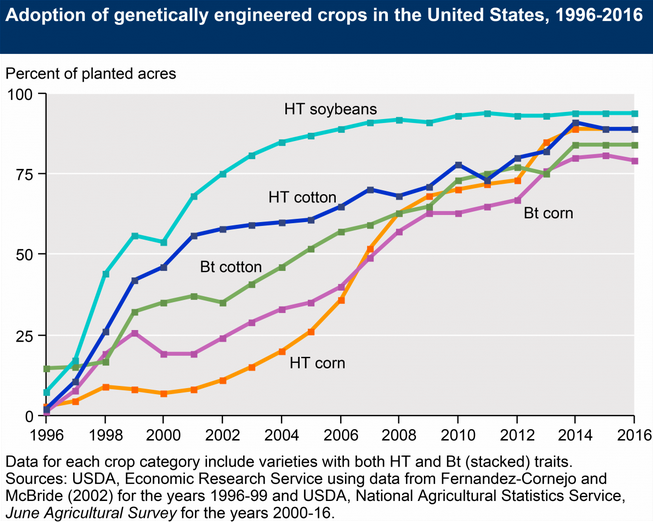

Unfortunately, most corn available in the U.S. comes from cultivars that are genetically modified to be resistant to pesticides like glyphosate which is extensively applied.

Cereals

Breakfast cereals are among the most extensively processed grain foods. Processing includes the shaping of flakes and other forms needed to satisfy marketing and consumer demands and expectations.

Preservatives, artificial colors, and other chemicals are added in addition to the conveyor, piping, tubing, and other opportunities for contamination by BPA and phthalates.

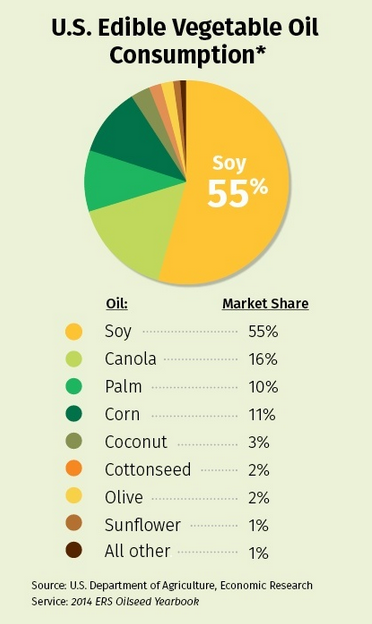

Edible Oils

Edible oils are often chosen for their flavors (such as in salads), or their behavior in a frying pan, baking, or other forms of cooking.

This article from a popular web site — Healthy Cooking Oils — outlines culinary uses and touches upon various health relationships. (While the article makes several over-generalized judgments regarding health, it is a good overall review for both cooking and health assessments and one of the better articles in this regard.)

Producing edible oils

The standard oil-producing process involves plastic pipes, tubing, pump components, bins, tanks, conveyor belts, and associated sources of contamination. Contamination increases with each additional processing step.

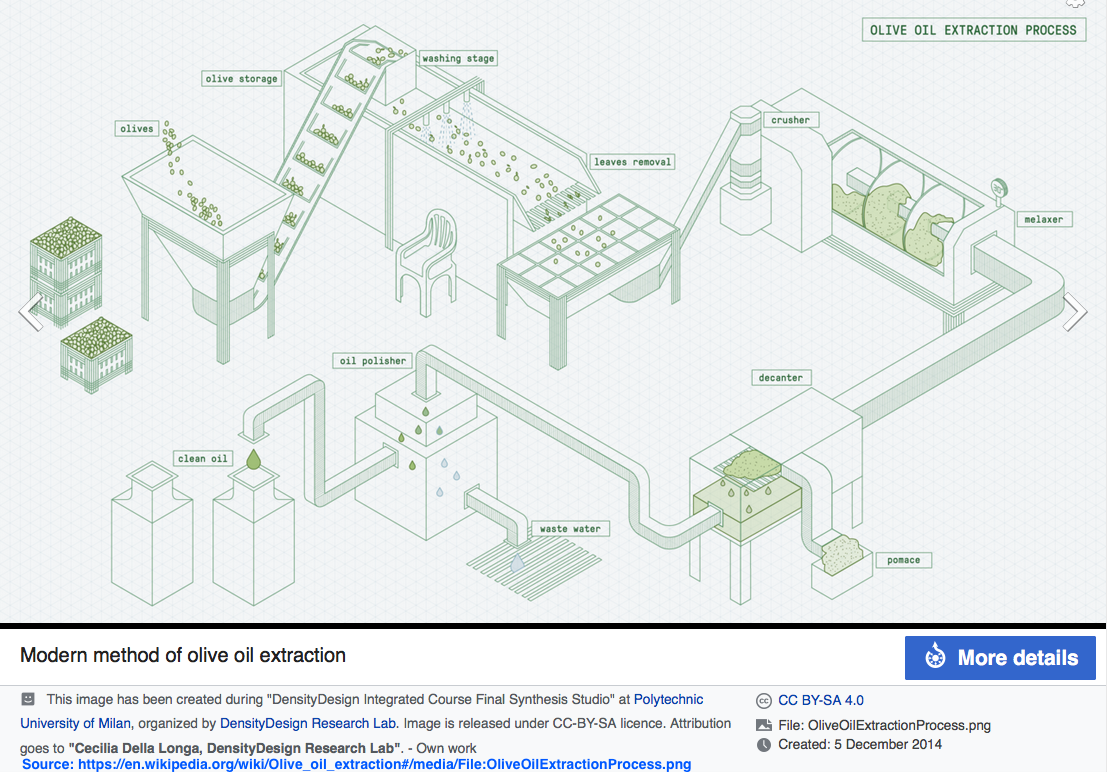

Producing edible oils from seeds, nuts, and fruits begins with mechanical extraction by crushing or pressing the raw stock. That recovers a portion of the oil.

Once pressed or crushed, additional oil can be produced by heating the pomace.

In many cases, heating is followed by solvent extraction using various petroleum distillates such as hexane to dissolve the remaining oil from the pomace.

Because the solvent has a much lower boiling point than the oil, most of the solvent is removed by a distillation process that recovers most of the solvent for reuse. Small but detectable amounts of the solvent are impossible to remove and will remain in the finished oil.

No government regulations exist to require disclosure of the process.

Harvest & Processing

High-production edible oils such as soy, canola, and corn involve mechanical harvesting that involves the plastic contamination sources common to other fruits and vegetables: conveyor belts, plastic chutes, bins, gloves, processing vessels, and associated components.

Olive Oil

First. avoid the “organic” pesticides.

The Olive fruit fly is endemic in California and other wine-producing regions around the world. There are a variety of methods for controlling infestations including baits, traps, attractant strips, and certified organic pesticides such as Spinosad and Surround. (UC Pest Management Guidelines).

Despite their organic-certified status, both Surround and Spinosad contain toxic chemicals and proprietary chemicals whose identities are trade secrets and not disclosed. Because of this, olives treated with these are unacceptable.

Untreated olives or those produced in groves using baits, traps, or attractant strips are acceptable.

Olives undergo a washing process — a water rinse — before pressing. There are many other stages, some of which commonly use plastic components in the process.

Visits will be made to determine which oil press minimizes the use of plastic components.

Pressing

In the case of olive oil, the “first cold press” that takes place without heating produces maximum flavor.

Internationally, there is great confusion — and often scandal — over the regulation of grades and quality of olive oil that follow first cold press. Heating and solvent extraction are used in cheaper grades. Regulation is inconsistent and unreliable.

Significantly, heating drives off many of the aromatic compounds and reduces the healthy polyphenols in olive oil.

First cold press offers a consumer the best assurance of purchasing the healthiest edible oil product while minimizing plastic chemical contamination.

However, as healthy a first cold press is, harvest involves plastic bins, rakes and, synthetic fiber netting. What’s more, the production process involves plastic bins, conveyor belts, pipes, tubing, pump components, filters, and more.

Edible oil & genetic engineering (Hard for some people to swallow)

At least half of all vegetable oil consumed in the United State comes from genetically engineered crops. The genetic modifications are usually made to make the crop plant resistant to herbicides which are copiously used. In addition to the controversy concerning effects of glyphosate and other active ingredients, no research is available on adjuvants and/or other chemicals that are undisclosed or are trade secrets.

The scientific evidence concerning the safety of GMO organisms is hotly disputed. We have no evidence that GMO foods would affect our test results in any way. However, out of an abundance of caution and for the sake of reproducibility, the study will not chose those foods for the diet.

Candy, snacks, protein and meal-replacement bars (nope)

Candy, snacks, protein, and meal-replacement bars are among the most extensively processed foods available.

Candy and snacks tend to be ultra-high fat and/or sugar products. The fat content offers a significant opportunity for the concentration of lipophilic chemicals such as BPA and phthalates.

Chips made from non-GMO corn raised organically and fried in oil which is similarly organic and non-GMO in origin would be acceptable if available.

Nutrition bar contamination

Bodybuilders, people in a hurry and those who opt for a balanced nutrition bar instead of candy bar are, however, getting extra doses of harmful environmental chemicals because these are among the most highly processed foods available.

In addition to the BPA and phthalate exposures inherent in the processing regime, the protein in these bars comes primarily from either soy or whey.

Soy presents a dual concern because it adds compounds that exert estrogen-like effects. I addition, almost all soybean crops are composed of genetically modified cultivars engineered to be immune to the application of pesticides including glyphosate.

Because of soy’s estrogenic effects, many people currently buy bars fortified with whey protein left over from cheesemaking. However, whey presents the same environmental chemical concerns as dairy.