When we conducted the investigation for our 2022published paper, the goal was to create a menu that was a “typical” American diet as defined by the U.S. Department of Agriculture.

That “typical” diet demanded that we include cow’s milk. And that was a problem.

Dairy has many opportunities for plastic contamination

For dairy products, we created an ultra-strict sourcing protocol that assumed that the introduction of plastic chemicals into the dairy food chain begins with the milking process. That strict protocol had to be drastically altered will be described below.

To consumers, the most obvious connection between plastic and dairy products comes in packaging — shrink wrap, plastic bottles (“paper” bottles have plastic coatings), plastic yogurt containers, butter in plastic tubs or wrapped in paper impregnated with chemicals.

This ad-free article is made possible by the financial support of the

Center for Research on Environmental Chemicals in Humans: a 501(c)(3) non-profit.

Please consider making a tax-deductible donation for continued biomedical research.

Additionally, previous studies — including dietary interventions — have focused primarily on packaging materials as sources of contamination. H0wever, the dairy chain’s many contamination sources from plastic-derived chemicals (BPA and phthalates involves numerouds additional contacts with plastic and other chemicals before it reaches the consumer. Some of those contacts include: include

- “teat washes” to clean and disinfect cow udders, as well:

- polymer filters to screen out dairy and other foreign matter,

- hoses to transfer raw milk from the milking machine to holding tanks,

- hoses to transfer milk from holding tanks to transport tankers whose stainless steel tanks may have polymer liners and potentially traces of chemicals used for disinfection.

- More hoses are used to transfer milk from tanker trucks to the creamery which uses a variety of plastic and stainless steel components to process the milk and get it ready for sale to tee consumer.

In addition, once at the creamery, there are polymer-based components used for the movement of milk through filtering, pasteurization, cream separation, homogenization, and finished packaging.

Dairy contamination begins with what the cow eats

While there are few studies studying the presence of plastic chemicals in milk produced by American dairy cows, work in Europe <citations to be added here and elsewhere in final version> indicates that milk produced in warmer weather when cows are eating in pastures seems to have fewer contaminants than when they are fed manufactured (processed) feed in colder weather.

Because of the extensive contamination from feed to consumption our original approved protocol for sourcing milk demanded that we start as low as possible on the processing chain.

That approved protocol required us to obtain certified organic raw milk from cows raised in pastures that were not irrigated. Especially, not irrigated with recycled municipal wastewater which contains scores of pharmaceutical byproducts, illegal drug metabolites, and toxic chemicals.

Our plan for the raw milk was to obtain the milk directly from the milking machine.

While milking machines use many plastic components, we were prepared to pay for replacing the most common plastic parts with ones that were known not to leach BPA and phthalates.

Processing, transparency, source traceability and reproducibility

The most reproducible results for our study meant we had to start with the least-contaminated dairy products.The logic dictated that, if we knew where the raw milk came from, we could trace the source for the cheese (for cheeseburgers and sandwiches), the butter (to be used as the only oil for cooking), and the milk products for consumption.

That also meant that we would rely on those resulting dairy products were to use in preparing other foods. Because of that, dairy became a foundational role for the study’s entire menu. For more on that, see Menu: Dairy – Milk, Cheese, Yogurt, Butter.

In addition, the wide variety of possible materials and used by individual dairies and creameries, plastic contamination levels are likely to vary significantly from one operation to the next. That, we reasoned, would mean that other investigators wishing to replicate our study might could might up with substantially different conclusions unless they obtained raw milk from our source and used the same methods and materials we did to process raw milk.

That requirement meant that processing our own raw milk and resulting foods could make our study more reproducible. Because reproducibility is a key foundation of a well-conducted investigation, we were ready to exert the extra effort.

Based on this set of assumptions, we hypothesized that the minimum contamination and the best chances of replicability of the study protocol demanded a “back to the future” effort that required us to acquire raw milk — milked by hand (with conditions).

Once we had obtained the raw milk, the protocol required that we:

- Filter the raw milk to remove physical contaminants such as hair.

- Pasteurize the milk.

- Separate the cream from the milk.

- Use the cream to make butter which we would use as our basic fat/oil for cooking.

- Make yogurt

- Use the lower-butterfat (approximately 4%) milk from the separation for cooking and direct consumption.

- Make cheese.

By taking on so many basic processing steps, we could minimize plastic contamination by making sure that only glass and stainless steel came in contact with the milk once we had obtained it from the milking machine.

Based on our study protocol revision approved by the Committee on Human Research at the University of California San Francisco Medical School, in latye 2018, we began to contact Sonoma and Marin County dairies, creameries, farm organizations, and agriculture-related educational institutions.

Unexpectedly, we ran into a stonewall of silence and lack of cooperation from the dairy industry. Over a period of eight months least 43 phone calls and emails to dairies, creameries, went un-returned. We failed to get even a reply from dairies, creameries, farm organizations, ag-oriented educational institutions — even — cheese and yogurt makers — anyone who might know a dairy farm who would cooperate.

When that produced no results, we resorted to personal visits and “milk driving” around Sonoma and Marin County looking for any dairy or cheesemaker who might be willing to help direct us to a source of milk. Every door we knocked on remained shut. That included Cooperative Extension and the Farm Bureau.

The the dairy industry’s refusal/inability to cooperate set the study back by at least nine months and required a one-year extension by the UCSF Committee on Human Research.

That frustrating effort is told in more detail in this DRAFT post “No milk for research!” (A Sisyphian tale … still in progress).

Aggravating the milk acquisition problem was the fact that the cream separator acquired — warranted by the seller to have stainless steel components and no plastic — had — upon inspection — many plastic parts and seperator components that were either aluminum or low-grade stainless steel.

New confounding problems force significant dairy protocol changes

The lack of cooperation from dairies and creameries combined with the inability to obtain an appropriate cream separator sent us back to our towering pile of scientific literature in search of a valid path from this latest dead end.

That new look at our “to be read” revealed a relatively recent 2019 paper that had been published after we had done our massive 2018 protocol revision.

That paper upended our concept that the least-contaminated milk would be obtained by hand, rather than via machine milking which has many plastic components.

That paper noted that, “The mean BPA concentrations were 0.757 µg/L in manually milked samples, 0.580 µg/L in mechanically milked samples, and 0.797 µg/L in milk from the cooling tank.”

Unexpectedly, the hand-milked had a higher concentration of BPA than milk samples obtained by machines.

That sent us back to an extensive literature search which revealed that there is little data done on looking at BPA/phthalate contamination along the entire dairy production chain. However we found a remarkably thorough 2012 paper that looked at the entire chain beginning with groundwater.

That paper found that phthalate concentrations were inconsistent: machine-milked samples were sometimes more contaminated than those obtained by hand … and vice-versa.

While not mentioned by either of these two papers, it’s notable that people who hand-milk cows wear polymer-based gloves which could be a source of contamination.

Regardless, these study results of inconsistencies disproved our hypothesis that the least-contaminated milk would come from hand milking.

Even more significantly, the study found further inconsistencies in contamination depending upon the seasons, silage (feed) as well as in the cooling tanks, and the trucks used to transport the raw milk to the creamery.

Those inconsistencies are further complicated by variations in the presence of plastic materials associated with different creamery operations: pasteurization, cream separation, homogenization and consumer packaging.

This meant that there was no valid way of predicting BPA/phthalate levels based upon intercepting samples at the milking stage.

Finally, because the dietary significance of dairy demands that it be included in our intervention diet, the only remaining tactic was to have commercial samples directly tested to select the “before” source and the “after.”

And that choice meant that we would have milk to drink, the lack of a valid cream separator meant that making butter and most cheeses would be impractical given the 4% butterfat of commercial milk.

Mass Spectroscopy to the rescue

Confounding factors and the goal of maximizing the opportunities for replication meant that investigators needed to include commercially available dairy products in the study diet. That inclusion meant that mass spectroscopy was theonly viable choice to find brands that were the least contaminated by BPA and other plastic chemicals to use in the “after” leg of the study.

Once the decision was made to use mass spectrometry, investigators contacted the academic institutions that were likely to have the ability to assist with mass spectroscopy: The Ag School at the University of California, Davis and Cal Poly San Luis Obispo. Surprisingly, multiple contacts at Davis told us that no one there knew how to run mass spec on milk. Cal Poly SLO failed to respond.

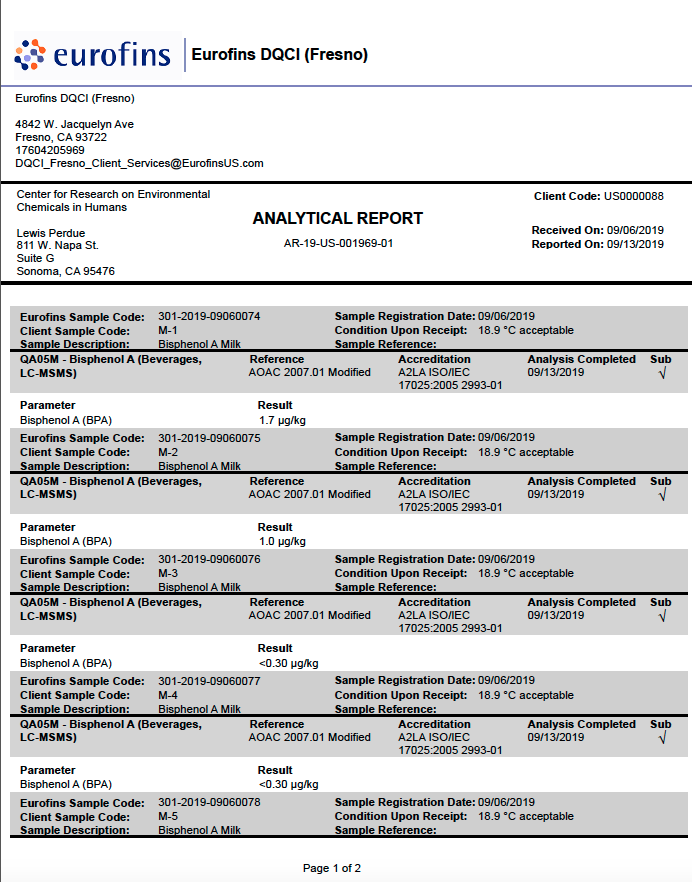

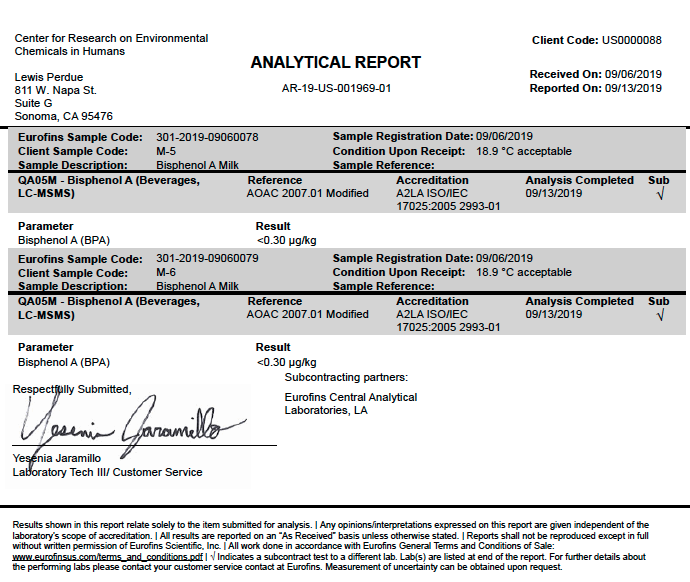

Investigators then contaced commercial labs which routinely analyze food and beverages among other substances. Chosen was Eurofins a large international commercial laboratory corporation because of numerous recommendations. The company also has a facility in Fresno specializing in food analysis that is accredited to the ISO 17025.

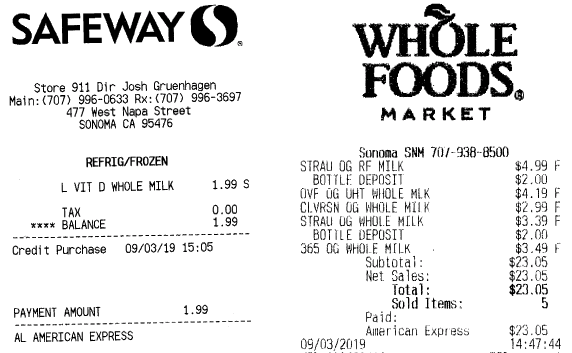

All milk samples were sourced at Whole Foods Market and Safeway in the town of Sonoma on September 3, 2019.

Investigators attempted to avoid plastic packaging which has higher levels of BPA and phthalates, but the Whole Foods milk was only available in plastic. Straus was only available in glass. All are whole milk ( approximately 4%) except for the 2% reduced fat.

In order for this analysis to be reproducible by other investigators, investigators selected products that are easily obtainable nationwide. Those opportunities are enhanced by obtaining them at a national (Whole Foods) or a very large regional chain (Safeway).

The Straus products were chosen for analysis because their website notes that they are an organic creamery that employs “minimally processed” procedures and is packaged in glass to avoid plastic food contact chemical contamination. Investigators hypothesized that Straus products would be a likely baseline and show the lowest BPA levels.

The milk with the highest level was intended to be used be used in the “before” diet and the lowest in the intervention. Because Straus is not available nationally, its inclusion in the testing was simply intended as a measure of how low BPA levels might go.

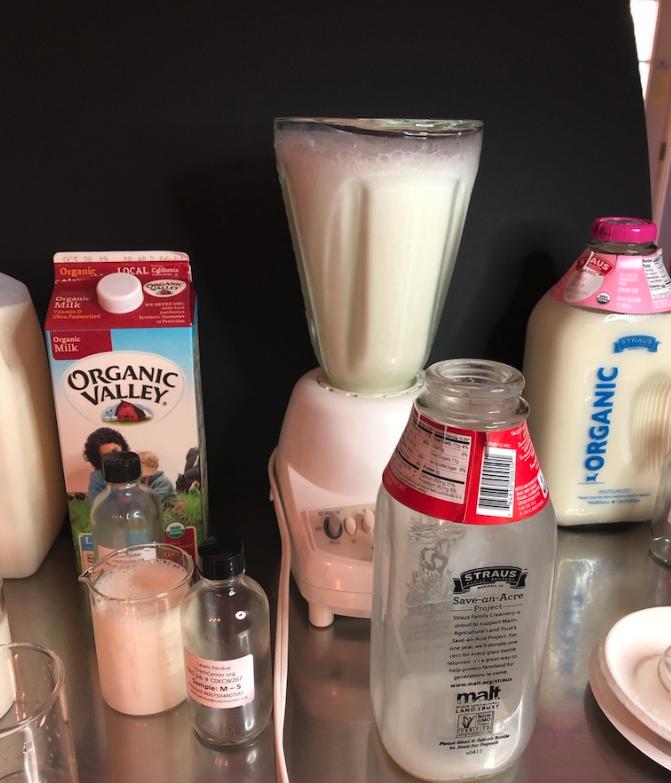

From left to right: Safeway supermarket brand, Clover (large local creamery), Whole Foods Brand, Organic Valley, Straus Family Creamery (local organic creamery) and Straus Family Creamery 2% Right click photo for a much larger imageAll samples remained unopened until samples were to shipped to Eurofins.

One day after purchase, the samples were re-packed in 120ml, “Boston style” clear glass bottles which were washed and triple rinsed with MultiPure carbon-filtered water before use. Straus whole milk is pictured with glass and metal blender to note that cream had solifified at the top of the bottle and needed to be thoroughly blended before the Mass Spec sample was collected for analysis.

One day after purchase, the samples were re-packed in 120ml, “Boston style” clear glass bottles which were washed and triple rinsed with MultiPure carbon-filtered water before use. Straus whole milk is pictured with glass and metal blender to note that cream had solifified at the top of the bottle and needed to be thoroughly blended before the Mass Spec sample was collected for analysis.

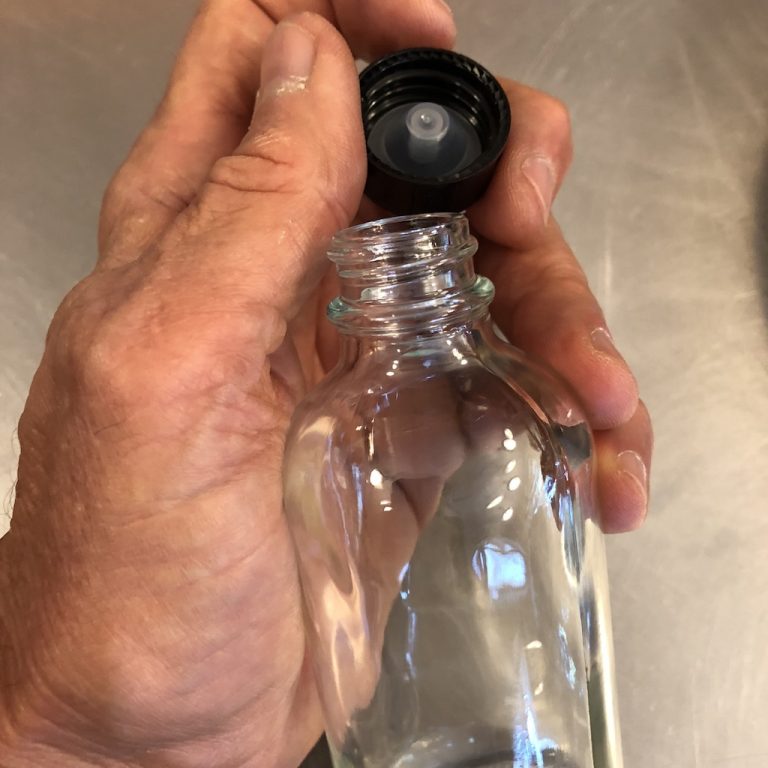

After filling, the mouths of the bottles were covered with Reynolds Wrap extra-thick aluminum foil to prevent contact with the plastic screw caps.

For more on how the caps were fabricated, see: Making aluminum foil barriers to avoid contamination by migration of plastic bottle caps.

Bottles inserted in a zip-closure-type plastic bag in case of leakage then were individually covered with bubble wrap to prevent impact damage in shipping

Results

Test results below (top to bottom) reflect the left-to-right order of specific milk containers in the top photo.

Relevant supplemental links

Hot topic: Bisphenol A in cow milk and dietary exposure at the farm level

Phthalate Concentrations and Dietary Exposure from Food Purchased in New York State Published:1 April 2013https://doi.org/10.1289/ehp.1206367 (open access)

Phthalates in Belgian cow’s milk and the role of feed and other contamination pathways at farm level https://doi.org/10.1016/j.fct.2012.05.036

Determination of free and total phthalates in commercial whole milk products in different packaging materials by gas chromatography-mass spectrometry https://doi.org/10.3168/jds.2015-10066

Final Choices

Two of the six samples tested above the 0.3 micrograms/kilogram (ppb) Level of Quantification (LOQ) of the Eurofins testing method. Of those two, Safeway was chosen for the “typical” diet because it is the house brand of a large regional chain. Similar milk is likely (but not guaranteed) to be available from other large regional chains.

The Clover Organics was not chosen for the “typical study leg because it is a local creamery. However, it does illustrate that simply choosing “organic” is not as guarantee of low contamination by plastic chemicals.

Of the four brands that were below the LOQ, The Straus samples packed in glass were not chosen because they are local brands.

Of the remaining brands, the Whole Foods was packed in plastic and the Organic Valley in paper with a plastic lining. More sensitive mass spectrometry would be needed to determine the relative BPA levels among Straus, Whole Foods and Organic Valley. However, for the purposes

The logic of selecting Organic Valley

Organic Valley was selected for two reasons. It is:

Available nationwide in a wide variety of supermarkets and groceries, which makes it more widely available than Whole Foods, and

A cooperative that operates creameries which also make butter and cheese. While there is no certainty that their butter and cheese will have lower levels of BPA than other brands, the below-LOQ nature of its milk is an indicator.

The cheese/butter dilemma

Because raw milk — before cream separation — is not available in grocery stores we also needed to find cheese and butter sources as well. The best decision we could make was to obtain butter and cheese from the same source of milk that Mass Spec said was the least contaminated.

A final confounding factor with commercial dairy

Sourcing products from national chain stores helps reproducibility because most food items will be the same from store to store within the chain.

This situation fails with fresh products like vegetables and dairy which are often obtained from local or regional sources.

Meat items are often nationally distributed. But consistency on sources is why we chose frozen beef patties and entrees for some “typical” menu items.